ホームページ About Us EVENTS & NEWS Choosing the Right EV Battery Management Systems: Technical Insights and Product Comparison

Choosing the Right EV Battery Management Systems: Technical Insights and Product Comparison

Choosing the Right EV Battery Management Systems: Technical Insights and Product Comparison

As electric vehicles (EVs) continue to redefine the future of transportation, the demand for efficient and intelligent EV battery management systems has become more critical than ever.

A high-quality battery management system (BMS) is the brain behind safe, reliable, and long-lasting EV battery operation.

The following section will present an analysis and comparison of the technical basis, core components and functions of EV battery management systems.

How Do EV Battery Management Systems Work?

The operation of EV battery management systems can be summarized in three stages:

Sensing: Sensors collect voltage, current, and temperature data in real-time.

Processing: The central control unit evaluates this data using embedded algorithms.

Acting: The BMS performs actions such as disconnecting circuits, triggering alerts, or adjusting charging behavior.

These systems not only improve operational safety but also enhance battery longevity by managing depth of discharge and thermal cycling.

Structural Design of EV Battery Management Systems

A complete EV battery management system consists of multiple hardware and software layers:

Battery Monitoring Unit (BMU): Gathers real-time electrical and thermal data.

Master Control Unit: Central processor for logic execution and safety response.

Slave Boards: Manage cell groups in large packs.

Balancing Circuit: Equalizes cell voltages passively or actively.

Communication Interface: Integrates with vehicle electronics and diagnostics tools.

Protection Circuits: Isolate the battery under fault conditions.

This modular structure allows flexible integration into various EV configurations.

Functions of EV Battery Management Systems

EV battery management systems are electronic control units that monitor, manage, and protect the battery pack in electric vehicles.

Their purpose is to ensure the battery operates within safe electrical, thermal, and mechanical limits while optimizing performance and lifespan.

Core Functions of EV Battery Management Systems:

Voltage Monitoring: Ensures cells stay within optimal voltage ranges.

Temperature Monitoring: Prevents overheating and thermal events.

Current Management: Avoids overcurrent and short-circuit risks.

State Estimation: Calculates State of Charge (SOC) and State of Health (SOH).

Balancing: Maintains uniform voltage across battery cells.

Data Communication: Sends real-time data to the vehicle’s ECU via CAN, RS485, or other protocols.

How to Choose a Better Car Battery Management System

Choosing the right BMS for a car battery involves evaluating several critical factors:

Compatibility

Ensure the BMS supports your battery type (e.g., lithium-ion, LFP) and voltage range (e.g., 12V, 48V).

Safety Features

Look for protection functions such as overcharge, over-discharge, overcurrent, and thermal protection.

Cell Balancing

A quality BMS should offer efficient passive or active balancing to extend battery life and maintain performance.

Monitoring and Accuracy

Choose a BMS with high-precision voltage, current, and temperature sensing to ensure accurate state estimation (SOC, SOH).

Communication Protocols

Select a BMS with reliable communication options like CANBus or SMBus for easy integration with the vehicle’s control systems.

Customization and Scalability

For EVs or commercial vehicles, a scalable and customizable BMS is essential for adapting to different battery configurations.

Supplier Reputation

Work with trusted BMS manufacturers like Shenzhen Ayaa Technology Co., Ltd., known for delivering reliable and innovative BMS solutions across global markets.

AY-L24S300A-LES001 (7S–24S): Ideal for High-Power EV Platforms

The AY-L24S300A-LES001 is a flagship product from Shenzhen Ayaa Technology tailored for demanding EV applications that require large voltage support and intelligent monitoring.

Technical Highlights:

Voltage Range: 7S to 24S lithium packs

Current Capability: Supports up to 300A

Communication: CANbus-enabled for real-time diagnostics

Protection: Full suite including OVP, UVP, OTP, OCP

Use Cases: Passenger EVs, commercial EVs, energy storage-integrated EVs

This model exemplifies how advanced EV battery management systems can ensure stability and performance under high load conditions.

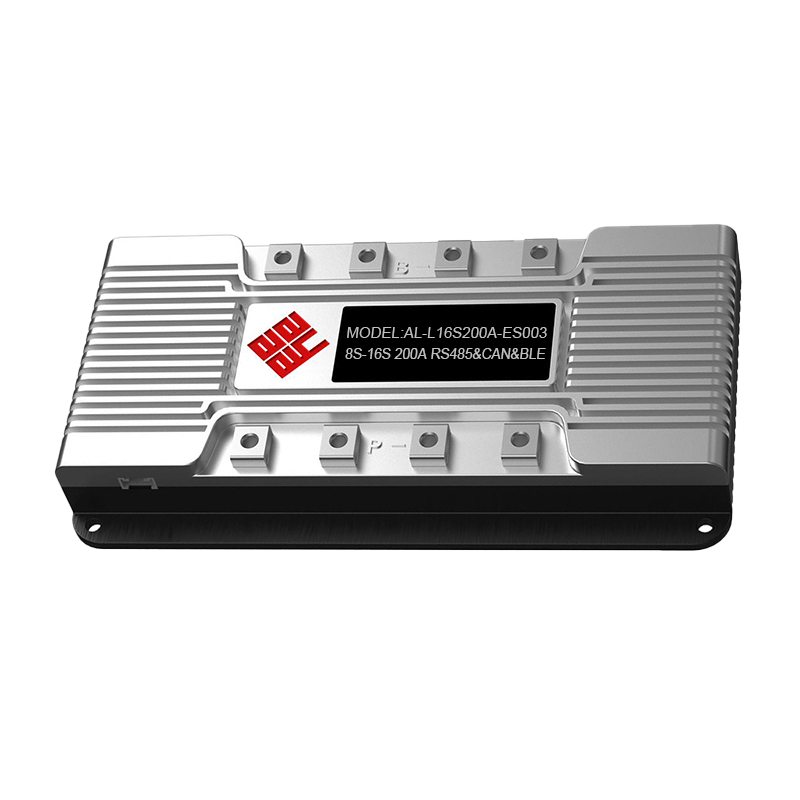

AY-L16S200A-ES003 (8S–16S): Best for Parallel Configurations and Communication Flexibility

The AY-L16S200A-ES003 stands out for its compatibility with parallel battery pack setups and rich communication interfaces.

Product Features:

Voltage Range: 8S to 16S configurations

Current Rating: 200A

Protocols Supported: CAN, RS485, SMBus

Parallel Operation: Seamlessly manages multiple battery strings

Applications: Off-road EVs, electric trucks, scalable energy vehicles

For developers seeking reliable and scalable EV battery management systems, this unit delivers broad integration capabilities.

AY-YY8S400A-H240 (8S): High-Current BMS for Performance Vehicles

When high current output is crucial, the AY-YY8S400A-H240 offers exceptional performance.

Key Advantages:

Voltage Support: 8S battery pack

Current Handling: Up to 400A continuous

Smart Monitoring: CAN-enabled, high-frequency data transmission

Durability: Designed for rugged and thermally challenging environments

Use Cases: High-performance EVs, racing electric vehicles, heavy-duty electric platforms

Its robust current capabilities make it one of the most advanced EV battery management systems for aggressive driving conditions.

Product Comparison Overview

AY-L24S300A-LES001 7S–24S 300A CAN Applications: Passenger/commercial EVs, ESS-integrated

AY-L16S200A-ES003 8S–16S 200A CAN, RS485, SMBus Applications: Off-road EVs, modular systems

AY-YY8S400A-H240 8S 400A CAN Applications: High-performance EVs, motorsports

This side-by-side comparison helps manufacturers and integrators evaluate the best EV battery management systems for their specific use cases.

FAQ

Q:What is the battery management system in EV?

A:An electrical component of an electric vehicle (EV) called a Battery Management System (BMS) keeps track of and regulates the battery pack’s performance.

By controlling important variables like voltage, temperature, and level of charge, it guarantees the battery runs safely, effectively, and dependably.

Additionally, the BMS is essential for maintaining the proper balance of charge levels in each individual cell, avoiding overcharging or undercharging, and prolonging the battery’s life.

Q:How does a battery management system work?

A:In response to variations in cell voltage, the battery management system balances the cells.

It balances the cells and ensures that they are all operating at the same voltage by transferring energy between them.

Q:What does lithium battery BMS do?

A:Battery Management System is referred to as BMS.

The BMS guards against damage to the cells, which is typically caused by external short circuiting, high temperatures, excessive current, or undervoltage.

In order to safeguard the cells from hazardous operating situations, the BMS will cut the battery.

Why Choose Shenzhen Ayaa Technology Co., Ltd.?

Shenzhen Ayaa Technology Co., Ltd. is a pioneer in developing advanced EV battery management systems, with over 20 years of industry expertise. What sets AyaaTech apart:

400+ BMS Models: Covering 1S to 35S configurations

Current Capacity: From 1A to 320A

Global Integration: Products used in EVs, drones, robotics, AGVs, and more

Modular Design: Easy to customize for voltage, communication, and thermal strategies

Certifications: ISO, CE, RoHS, UN38.3-compliant

With a reputation built on quality, precision, and client support, AyaaTech continues to push the envelope in EV battery management systems.

Selecting the right EV battery management systems is essential to the success of any electric vehicle project.

By understanding the core technology, structure, and available product options, manufacturers can make informed choices that balance safety, performance, and scalability.

Products like the AY-L24S300A-LES001, AY-L16S200A-ES003, and AY-YY8S400A-H240 from Shenzhen Ayaa Technology offer unmatched functionality across various EV platforms.

For tailored BMS solutions that meet the evolving demands of electric mobility, Shenzhen Ayaa Technology Co., Ltd. is your trusted partner in innovation.