AYAA offers high-quality battery management systems for UAVs, drones, and robots. We provide wholesale options, OEM/ODM services, and reliable factory supply.

Home Products

Smart Battery Managment with Communications

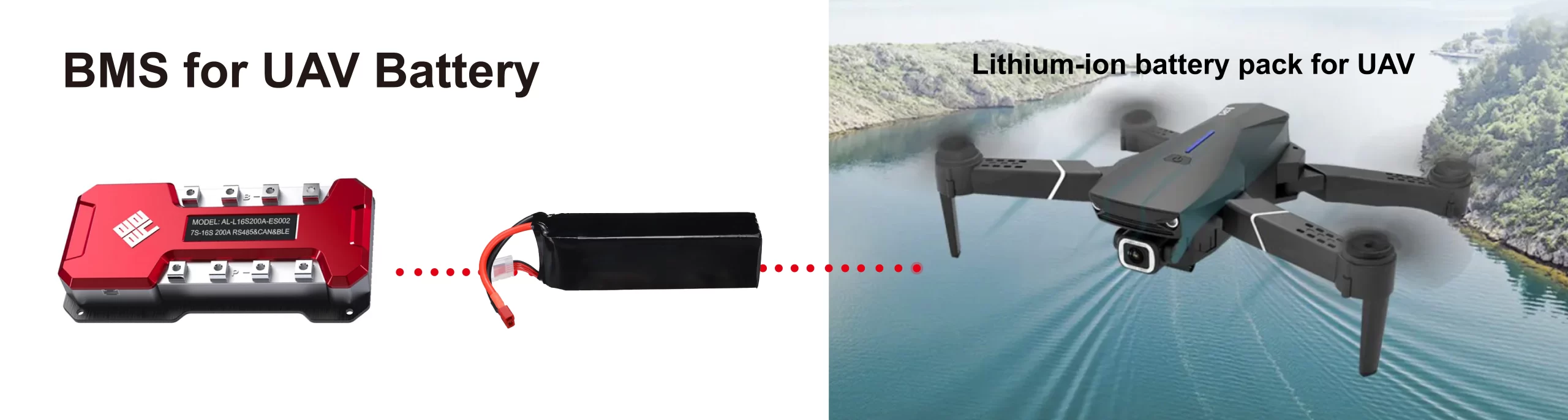

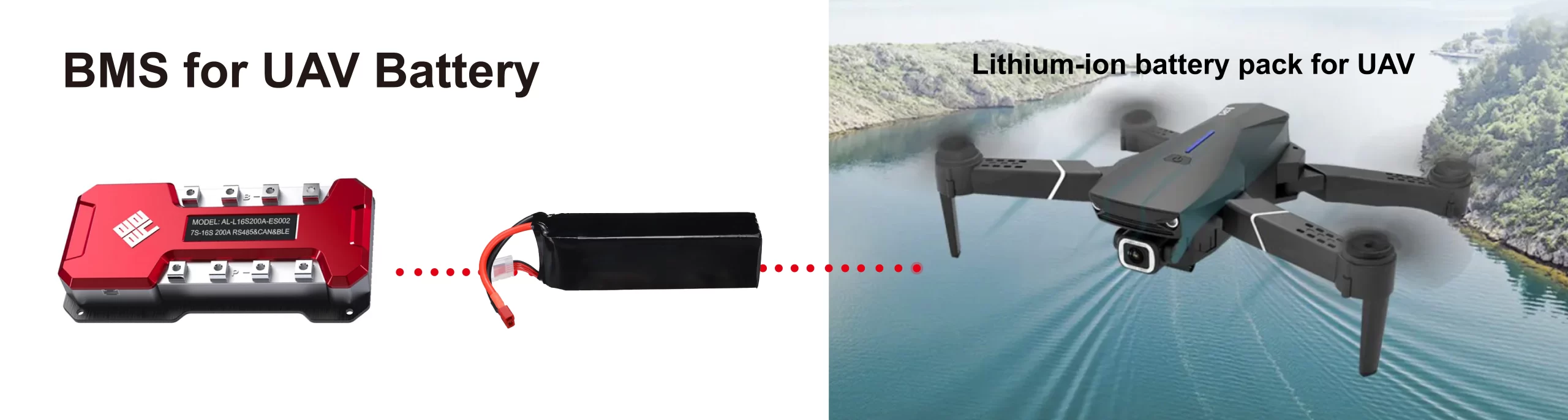

Modern Battery Management Systems (BMS) for UAV (Unmanned Aerial Vehicle) batteries are offered by Shenzhen Ayaa Technology Co., Ltd. For UAV applications, our BMS solutions are developed to optimize battery performance, guarantee safety, and extend battery life. Our technology is perfect for commercial and industrial UAV operations because it optimizes energy utilization, supports long-duration missions, and improves flight reliability with accurate monitoring and control.

AYAA offers high-quality battery management systems for UAVs, drones, and robots. We provide wholesale options, OEM/ODM services, and reliable factory supply.

In the rapidly evolving fields of drones and robotics, the Battery Management System (BMS) serves as the critical "guardian" of power systems, ensuring safety, efficiency, and longevity. Whether addressing the sudden current surges during high-altitude drone operations or meeting the relentless demands of 24/7 warehouse robots, a robust Drone Battery Management System or Robot Battery Management System is indispensable. This article delves into the intricacies of BMS technology, exploring its foundational principles, advanced features, practical applications, and future trends. From real-time monitoring to intelligent diagnostics, we provide a comprehensive guide to understanding and leveraging battery management systems for drones and robots.

A Drone Battery Management System is an advanced electronic system designed to monitor, control, and optimize the performance of a UAV battery. Integrated within the battery pack, the BMS ensures safe and efficient operation by continuously tracking parameters such as voltage, current, and temperature. Its primary role is to safeguard the battery, extend its lifespan, and provide critical data to the drone’s flight control system.

The reliance on lithium-based UAV batteries introduces risks like overcharging, over-discharging, and thermal runaway. A battery management system for drones mitigates these risks by:

1. Voltage Monitoring: Tracks each cell’s voltage to ensure balanced charging and discharging.

2. Temperature Control: Utilizes sensors and cooling mechanisms to prevent thermal runaway.

3. Communication Interface: Employs protocols like CAN bus or UART for seamless interaction with the drone’s flight controller.

While both Drone Battery Management Systems and Robot Battery Management Systems aim to ensure battery safety and efficiency, their designs diverge due to distinct operational requirements.

For instance, in warehouse logistics robots, the Robot Battery Management System supports:

1. Fast Charging: Achieving 80% charge in 30 minutes to minimize downtime.

2. Precise SOC Algorithms: Enabling autonomous return-to-charge functionality.

In contrast, a Drone Battery Management System prioritizes lightweight designs, often reducing redundant circuitry to optimize payload capacity.

A typical UAV battery, such as a 6S lithium-polymer pack, consists of:

Cell Array: Multiple 3.7V cells connected in series (e.g., 6S = 22.2V) for high energy density.

1. Connect the charger; the Drone Battery Management System verifies cell voltages.

2. Initiates balanced charging, diverting excess charge from high-voltage cells via bypass resistors.

3. Switches to trickle mode upon full charge to prevent overcharging.

During high-wind conditions, the flight controller may request additional power. The battery management system for drones evaluates temperature and voltage within 2ms to decide whether to allow increased current (e.g., from 30A to 35A). Only intelligent BMS systems support such dynamic adjustments, while basic systems may abruptly cut power.

Application Example: In agricultural drones, the Drone Battery Management System adjusts discharge curves based on payload demands, such as pesticide spraying.

1. Data Collection: Samples cell parameters every 100ms.

2. Pattern Recognition: Detects anomalies by comparing against historical data.

3. Tiered Response:

Advanced Robot Battery Management Systems, like those in Tesla’s Optimus robot, use machine learning to model degradation, predicting battery end-of-life up to 30 days in advance.

Installing a Drone Battery Management System is critical for ensuring safe and reliable UAV operation. The process involves hardware setup, software configuration, and system testing.

1. Hardware Preparation: Verify the presence of the BMS board, battery pack, cables, and tools (e.g., multimeter, insulating tape). Ensure battery voltage matches BMS specifications.

2. Battery Connection: Connect the BMS to the battery pack with power off, following correct polarity and cell sampling line sequences to avoid damage.

3. Communication Setup: Configure CAN bus or UART parameters (e.g., baud rate, device address) to enable communication with the flight controller.

4. Parameter Configuration: Use dedicated software to set protection thresholds (e.g., overvoltage, undervoltage, overcurrent, temperature limits) based on battery specs and operating conditions.

Proper installation maximizes the battery management system for drones’ protective capabilities, preventing data inaccuracies or safety failures due to improper setup.

The lifespan of a UAV battery depends on charge-discharge management, storage conditions, usage frequency, and maintenance practices.

1. Optimized Charging: Use dedicated chargers with 0.5C–1C currents, maintaining temperatures between 5–35°C.

2. Discharge Control: Limit discharge depth to 80% to prevent chemical degradation.

3. Temperature Management: Operate within 15–25°C for optimal performance, using insulation or cooling as needed.

4. Storage Conditions: Store at 50–60% charge in a dry, ventilated environment, checking monthly.

5. Routine Maintenance: Log charge-discharge data and inspect connectors and cell consistency regularly.

6. Load Matching: Select battery capacity based on payload and mission requirements.

7. Cycle Management: Perform full charge-discharge cycles every 10–15 shallow cycles.

8. Safety Monitoring: Equip a robust Drone Battery Management System for real-time parameter tracking.

These practices can extend UAV battery life by 30–50% and reduce safety risks, ensuring reliable power for drone operations.

In smart manufacturing and logistics, Robot Battery Management Systems are pivotal for ensuring reliable power and enabling intelligent operations. They support predictive maintenance and seamless integration with scheduling systems.

In manufacturing, a Robots BMS provides precise SOC and SOH data, enabling accurate runtime predictions for production scheduling. When battery levels drop below thresholds, the BMS triggers autonomous charging requests, ensuring uninterrupted operations.

In logistics, AGVs rely on Robot Battery Management Systems to model energy consumption based on routes and payloads. This allows for optimized task assignments, preventing mid-task power failures.

Advanced Robots BMS systems reduce downtime by up to 25% and extend battery life by over 40%. Cloud-based analytics further enable predictive maintenance, shifting from reactive to proactive strategies.

A UAV battery with an integrated Drone Battery Management System outperforms traditional batteries by acting as an intelligent “brain” for power management.

1. Enhanced Safety: Multi-layered protections (overvoltage, undervoltage, overcurrent, short-circuit, thermal) reduce accident risks by over 90%.

2. Extended Lifespan: Precise SOC/SOH algorithms and cell balancing extend UAV battery life by 50–80%.

3. Accurate Monitoring: Real-time data on capacity, resistance, and temperature ensures <5% error in runtime predictions.

4. Intelligent Management: Self-learning algorithms optimize charging and provide personalized maintenance recommendations.

5. Seamless Communication: Supports CAN, UART, and cloud integration for cohesive system operation.

Modern battery management systems for drones operate in –20°C to 65°C and meet IP65+ standards, ensuring reliability across varied conditions.

Selecting a Drone Battery Management System involves balancing electrical compatibility, functional requirements, cost, and scalability.

1. Voltage Compatibility: Match BMS to battery voltage (e.g., 14.8V for 4S, 22.2V for 6S) with ±10mV sampling accuracy.

2. Current Capacity: Ensure 30–50% margin over peak currents to handle high-demand scenarios.

3. Communication Protocols: Verify compatibility with CAN, UART, or I2C for robust data exchange.

4. Environmental Resilience: Select systems with wide temperature ranges (–40°C to 85°C) and high IP ratings for industrial use.

5. Feature Evaluation: Compare cell monitoring precision, temperature sensor count, and diagnostic capabilities.

A systematic approach ensures optimal BMS performance, enhancing system efficiency by 20–30% while minimizing costs.

The Drone Battery Management System and Robot Battery Management System are evolving into intelligent energy hubs.

These advancements will create a unified energy management ecosystem, enhancing the efficiency and safety of battery management systems for drones and robots.

The Drone Battery Management System and Robot Battery Management System are pivotal in advancing the safety, efficiency, and intelligence of UAVs and robotics. From real-time monitoring to AI-driven diagnostics, these systems are more than protective shields—they are performance accelerators. By mastering BMS technologies, practitioners can optimize equipment selection, maintenance, and troubleshooting, paving the way for safer and smarter autonomous operations.

www.ayaatech.com

Model Number PCM-L08S60-K38 Communication Interface I2C&Bluetooth Charging voltage DC:27.6V~33.6V CC/CV(3.45V~4.2V/Cell)8s Maximal continuous charging current 20-60A Maximal continuous discharging current 20-60A Normal operating-mode current 600 uA SLEEP operating-mode current 350 uA Balance current for single cell / Balance voltage for single cell / Over charge detection voltage 3.6-4.35V Over discharge detection voltage 2.0-3.0V Over charge current protection / Over current detection current 80-180A Short Protection YES Technical Specification size L136 *W80 *T11 mm NTC 10K Temperature switch 65 ℃(the batteries temperature) Weak currentswitch / Active balance / Heater / Braking Resistors / Other Parameter Low temperature protOperating Temperature Range -40~+85℃ Storage Temperature Range -40~+125℃ Temperature Parameter LCD display screen / LED light board / Bluetooth mode / 4G / GPS / Optional Configuration

www.ayaatech.com

Model Number PCM-L06S100-L34 Communication Interface I2C Charging voltage DC:20.7V~25.2V CC/CV(3.45V~4.2V/Cell)6s Maximal continuous charging current 30-100A Maximal continuous discharging current 30-100A Normal operating-mode current 600 uA SLEEP operating-mode current 350 uA Balance current for single cell / Balance voltage for single cell / Over charge detection voltage 3.6-4.35V Over discharge detection voltage 2.0-3.0V Over charge current protection / Over current detection current 90-300A Short Protection YES Technical Specification size L145*W105*T8mm NTC 10K Temperature switch / ℃(the batteries temperature) Weak currentswitch / Active balance / Heater / Braking Resistors / Other Parameter Low temperature protOperating Temperature Range -40~+85℃ Storage Temperature Range -40~+125℃ Temperature Parameter LCD display screen / LED light board / Bluetooth mode / 4G / GPS / Optional Configuration

www.ayaatech.com

Model Number PCM-L05S75-J49 Communication Interface SMBUS Charging voltage DC:17.25V~21V CC/CV(3.45V~4.2V/Cell)5s Maximal continuous charging current 20-75A Maximal continuous discharging current 20-75A Normal operating-mode current 600 uA SLEEP operating-mode current 350 uA Balance current for single cell / Balance voltage for single cell / Over charge detection voltage 3.6-4.35V Over discharge detection voltage 2.0-3.0V Over charge current protection / Over current detection current 1 60-240A Short Protection YES Technical Specification size L130 *W116 *T8 mm NTC 10K Temperature switch / ℃(the batteries temperature) Weak currentswitch / Active balance / Heater / Braking Resistors / Other Parameter Low temperature protOperating Temperature Range -40~+85℃ Storage Temperature Range -40~+125℃ Temperature Parameter LCD display screen / LED light board / Bluetooth mode / 4G / GPS / Optional Configuration

www.ayaatech.com

Model Number AY-L5S100A-M069 Communication Interface RS485&CANBUS&UART Charging voltage DC:17.25V~21V CC/CV(3.45V~4.2V/Cell)5s Maximal continuous charging current 30-100A Maximal continuous discharging current 30-100A Current consume in normal operation ≤25mA SLEEP operating-mode current ≤150uA Balance current for single cell 36-42mA Balance voltage for single cell 3.6-4.2V Over charge detection voltage 3.6-4.35V Over discharge detection voltage 2.0-3.0V Over charge current protection 40-120A Over current detection current 1 80-240A Over current detection current 2 90-300A Short Protection YES Technical Specification size L180 *W75 *T20 mm NTC 10K Temperature switch / ℃(the batteries temperature) Weak currentswitch YES Active balance / Heater / Braking Resistors / Other Parameter Low temperature protOperating Temperature Range -40~+85℃ Storage Temperature Range -40~+125℃ Temperature Parameter LCD display screen / LED light board / Bluetooth mode / 4G / GPS / Optional Configuration

www.ayaatech.com

Model Number AY-L5S20A- M057 Communication Interface RS485&CANBUS Charging voltage DC:17.25V~21V CC/CV(3.45V~4.2V/Cell)5s Maximal continuous charging current 10-20A Maximal continuous discharging current 10-20A Current consume in normal operation ≤25mA Current consume in sleep operation ≤150uA Balance voltage for single cell 3.6-4.2V Over charge detection voltage 3.6-4.35V Charge Over current detection current 15-30A Discharge Over current detection current 1 20-40A Discharge Over current detection current 2 40-60A Short Protection YES Technical Specification size L80 *W60*T20 mm NTC 10K Temperature switch / ℃(the batteries temperature) Weak currentswitch YES Active balance / Heater / Braking Resistors / Other Parameter Low temperature protOperating Temperature Range -40~+85℃ Storage Temperature Range -40~+125℃ Temperature Parameter LCD display screen / LED light board / Bluetooth mode / 4G / GPS / Optional Configuration

www.ayaatech.com

Model Number AY-LB4S30A-T040 Communication Interface SMBUS Charging voltage DC:16.8V CC/CV(4.2v/Cell)4s Maximal continuous charging current 30A Maximal continuous discharging current 30A Current consume in normal operation ≤500uA Over discharge detection voltage 2.70±0.1V Over charge detection voltage 4.25±0.05V Charge Over current detection current 1 22±2A ChargeOver current detection current 2 30±2A Discharge Over current detection current 1 60±2A Discharge Over current detection current 2 70±2A Short Protection YES Technical Specification size L65 * W34.7 * T4 mm NTC 10k Temperature switch / ℃(the batteries temperature) Weak currentswitch / Active balance / Heater / Braking Resistors / Other Parameter Low temperature protOperating Temperature Range -40~+85℃ Storage Temperature Range -40~+125℃ Temperature Parameter LCD display screen / LED light board / Bluetooth mode / 4G / GPS / Optional Configuration

| Battery Series | Model | Picture | Working Current | Balance | Size | Remark |

|---|---|---|---|---|---|---|