AYAA, a leading China manufacturer, offers high-quality batteries for 3-wheelers, e-bikes, and electric bicycles. We provide wholesale options, OEM/ODM services, and reliable product supply for smart battery management systems.

Home Products

Smart Battery Managment with Communications

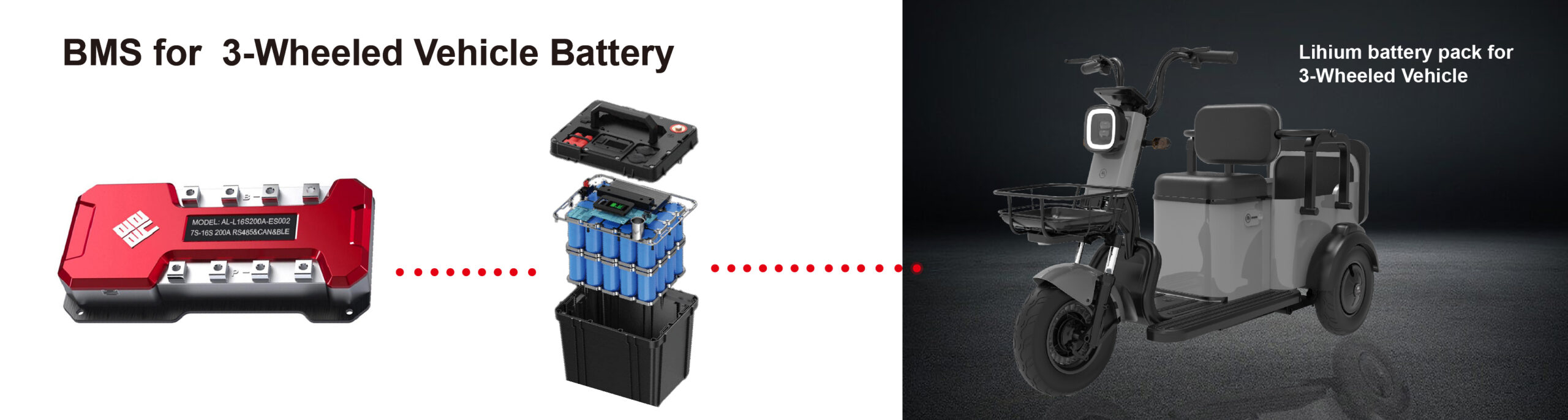

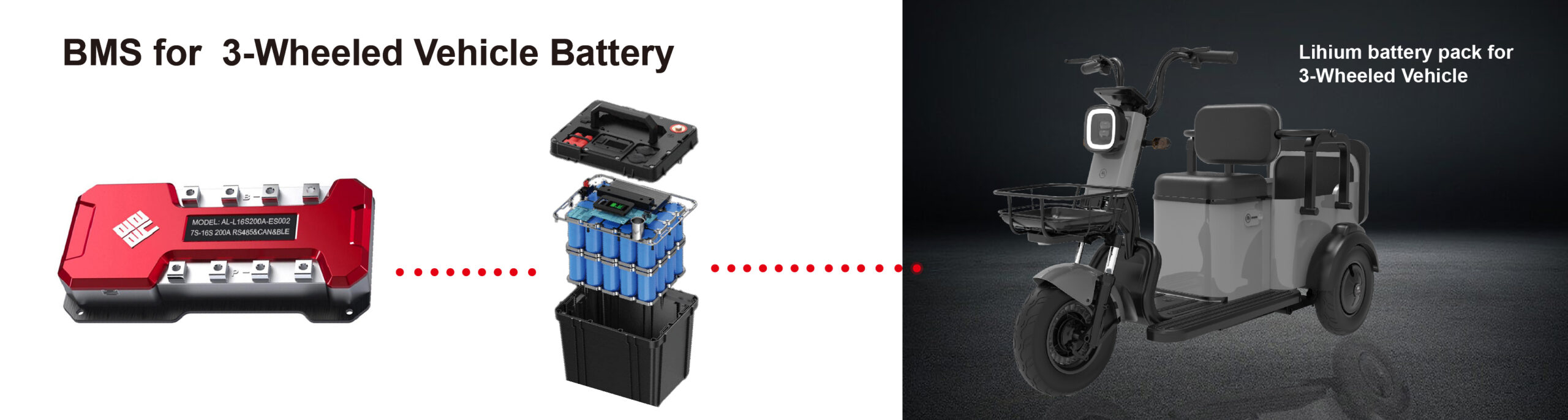

Strong Battery Management Systems (BMS) for three-wheeled vehicles are provided by Shenzhen Ayaa Technology Co., Ltd., guaranteeing dependable, effective, and safe power management. For electric tricycles and other three-wheeled electric vehicles, our BMS solutions are perfect since they are made to maximize battery performance, improve safety features, and lengthen battery life. We meet the increasing need for high-performing, environmentally friendly transportation options with our technology.

AYAA, a leading China manufacturer, offers high-quality batteries for 3-wheelers, e-bikes, and electric bicycles. We provide wholesale options, OEM/ODM services, and reliable product supply for smart battery management systems.

Electric tricycle and electric bicycle batteries are the core power sources that drive these vehicles, typically rechargeable lead-acid or lithium batteries. They provide energy to motors, supporting vehicle power output, lighting, and auxiliary systems. E-bike battery units are usually designed to be lightweight and easily removable for convenient charging, while 3 wheeler battery systems tend to have larger capacity and volume to handle greater loads.

These batteries store and release energy through electrochemical reactions, commonly operating at 36V or 48V with capacity ranges from 10Ah to 60Ah, depending on vehicle type and range requirements. Battery performance directly affects vehicle range, acceleration capability, and service life, making proper battery selection crucial.

Electric bicycle and electric tricycle batteries have significant differences in design and application. Understanding these differences helps in selecting the appropriate battery.

Define Usage: Choose lightweight lithium batteries for commuting e-bikes; select high-capacity batteries for transport tricycles

Budget Considerations: Lead-acid batteries offer low cost for budget-conscious users; lithium batteries provide superior performance at higher prices

Compatibility: Ensure battery voltage matches the controller to avoid performance bottlenecks

Lead-acid and lithium batteries are the two mainstream electric bike battery types, each with advantages and disadvantages suitable for different needs.

Lithium batteries better suit electric bicycle users pursuing performance in terms of range, weight, and lifespan, while lead-acid batteries are appropriate for budget-limited or short-distance usage scenarios.

Electric bicycle battery performance is determined by several key parameters. Understanding these parameters helps in selecting appropriate batteries and optimizing usage experience.

Voltage (V): Represents battery potential difference, commonly 36V or 48V. Higher voltage (like 48V) provides stronger power, suitable for hill climbing or high-speed riding

Capacity (Ah): Represents battery energy storage ability in ampere-hours. Higher capacity means longer range; for example, a 20Ah battery provides longer range than a 10Ah battery

Range: Affected by voltage, capacity, motor efficiency, and riding conditions. For instance, a 48V 20Ah battery can support 50-80km range under flat road conditions

Cycle Life: Represents the number of complete charge-discharge cycles possible; lithium batteries typically offer 800-2000 cycles, lead-acid batteries 300-500 cycles

Electric bicycle batteries achieve energy storage and release through electrochemical reactions, providing power for vehicles. Their working principle mainly includes charge-discharge mechanisms and battery management.

Charging Process: External power source converts electrical energy to chemical energy through a charger, storing it in the battery. For example, lithium batteries store energy through lithium ion movement between positive and negative electrodes.

Discharge Process: Battery releases chemical energy, converting it to electrical energy to drive the motor, with lithium ions moving from negative to positive electrode.

Monitors voltage, current, and temperature to prevent overcharging, over-discharging, or overheating

Maintains consistent individual cell voltage through balancing technology (active or passive balancing)

Lithium batteries achieve efficiency above 95%

Lead-acid batteries approximately 80-85%

1. Energy Storage: Battery charges fully through charger, storing chemical energy

2. Energy Release: During riding, battery discharges, transmitting electrical energy through controller to motor

3. Power Output: Motor converts electrical energy to mechanical energy, driving wheels

4. Status Monitoring: BMS real-time monitors battery status, optimizing performance and ensuring safety

5. Cycle Usage: Battery completes one charge-discharge cycle, repeating this process

Battery Management System (BMS) serves as the "intelligent core" of electric bicycle batteries, responsible for monitoring, managing, and protecting battery packs to ensure safe and efficient operation. BMS optimizes battery performance and extends service life through real-time detection of voltage, current, and temperature, widely applied in lithium battery electric bicycles.

BMS not only enhances battery safety but also optimizes energy utilization efficiency and extends battery life. For example, a 48V lithium battery equipped with BMS can support more stable range, suitable for long-distance riding.

Electric bicycle battery architecture consists of three components: cells, protection board (BMS), and housing design, each crucial for battery performance and safety.

Optimizing electric bicycle battery cycle life reduces replacement frequency and lowers long-term usage costs. Here are practical methods:

1. Check Charging Equipment: Confirm charger voltage and current match battery specifications

2. Set Charging Cycles: Charge to 80%-90% each time, avoiding 100% full charge

3. Monitor Usage Environment: Avoid riding in conditions above 40°C or below 0°C

4. Regular Calibration: Perform complete charge-discharge cycle every 6 months to calibrate SOC estimation

5. Check BMS Logs: Review battery health status through apps or software, addressing anomalies promptly

Sodium-ion batteries, as an emerging technology, are gradually becoming potential alternatives to lithium batteries, especially in the electric bicycle field.

With lithium resource price fluctuations and increasing environmental demands, sodium-ion batteries' low cost and high safety make them promising in the electric bicycle field, especially suitable for mid-to-low-end markets and extreme environments.

Selecting appropriate electric bicycle batteries requires comprehensive consideration of brand, capacity, and range requirements.

Proper installation and replacement of electric bicycle batteries is key to ensuring vehicle performance and safety. Whether installing new batteries or replacing old ones, following standard procedures prevents damage to batteries or vehicle systems.

1. Preparation: Confirm new battery voltage (36V or 48V) and capacity compatibility with vehicle controller. Prepare tools: screwdriver, multimeter, insulating gloves. Disconnect power, ensuring vehicle is in off state.

2. Remove Old Battery: Locate battery compartment, unlock or unscrew fixing screws. Disconnect battery connections to controller, avoiding short circuits. Carefully remove old battery, checking battery compartment for corrosion or damage.

3. Install New Battery: Place new battery in compartment, ensuring correct positive/negative connections. Secure battery, checking for stability without movement. Connect power lines, ensuring firm connections without looseness.

4. Function Testing: Use multimeter to check connection point voltage, confirming no abnormalities. Turn on to test vehicle, verifying normal battery power supply. Check SOC (State of Charge) data through BMS software or app.

5. Safety Check: Ensure battery compartment waterproof seal is good. Test brake and motor response, ensuring normal system operation.

Always operate in power-off state, avoiding electric shock

Use original or certified batteries, avoiding compatibility issues

Reference vehicle and battery manuals, ensuring correct connections

Proper charging methods are crucial for extending electric bicycle battery life. Fast and slow charging each have advantages and disadvantages; choose appropriate methods based on usage needs.

Low-temperature environments significantly reduce electric bicycle battery performance, especially affecting lithium batteries. Here are winter care tips:

Avoid Low-temperature Charging: Charging below 0°C may cause lithium plating in lithium batteries, damaging cells. Move battery indoors (15-25°C) for charging.

Preheat Battery: Before riding in cold weather, let battery sit at room temperature for 30 minutes, improving discharge efficiency.

Reduce High-load Usage: Battery capacity decreases in low temperatures; reduce rapid acceleration or hill climbing to extend range.

Storage Considerations: For long-term winter storage, maintain battery charge at 50%-60%. Store in dry, 5-20°C environment, avoiding freezing.

Check BMS Functions: Ensure BMS low-temperature protection functions normally, preventing over-discharge.

Insulation Measures: Use battery insulation covers, reducing temperature fluctuations

Choose Suitable Batteries: Sodium-ion batteries or low-temperature optimized lithium batteries perform better in cold environments

Regular Inspection: Monthly check battery voltage and health status, preventing low-temperature damage

Electric bicycle battery fires are mostly caused by thermal runaway in lithium batteries, especially with inferior batteries or improper usage. Understanding causes and taking preventive measures is crucial.

Inferior batteries may cause performance degradation, safety hazards, or even property loss. Understanding their dangers and learning to identify legitimate batteries is crucial for users.

Daily maintenance and safety checks of electric bicycle batteries are key to extending battery life and ensuring riding safety. Proper maintenance not only improves battery performance but also reduces failure and safety risks.

Check Battery Appearance: Inspect housing for cracks, deformation, or corrosion. Ensure connection terminals have no looseness or oxidation; regularly clean with dry cloth.

Monitor Battery Status: Check SOC (State of Charge) and SOH (State of Health) through BMS or apps. Monthly verify voltage normalcy, preventing individual cell imbalance.

Proper Storage: For long-term non-use, maintain charge at 40%-60%, storing in 15-25°C dry environment. Avoid humid or high-temperature environments preventing battery aging.

Safety Checks: Ensure charger specifications match battery, avoiding overvoltage charging. Check BMS protection functions like overcurrent and over-temperature protection.

Battery Management System (BMS) is the core of electric bicycle battery safe operation, preventing overcharging, over-discharging, and short circuits through real-time monitoring and protection mechanisms.

Preventing Overcharging: BMS monitors individual cell voltage; when reaching upper limits (like 4.2V/cell), cuts charging circuit. Uses balancing technology (active or passive) to balance cell voltages, preventing partial overcharging.

Preventing Over-discharging: BMS detects battery pack voltage; if below safety threshold (2.5V-3.0V/cell), disconnects discharge circuit. Provides low-power warnings, reminding users to charge promptly.

Preventing Short Circuits: Uses high-precision current sensors (like Hall sensors) detecting abnormal currents. When short circuits occur (within 250-500μs), triggers protection mechanism cutting circuits.

Additional Protection: Monitors temperature preventing overheating-induced thermal runaway. Supports fault diagnosis, recording abnormal data for troubleshooting.

BMS reduces battery fire or explosion risks through multiple protection mechanisms, extends battery life, and ensures riding safety. For example, 48V lithium batteries can safely operate 800-2000 cycles under BMS protection.

In 2025, the electric bicycle battery market is experiencing technological innovation and green transformation. Here are the main trends:

1. Rise of Sodium-ion Batteries: Sodium batteries gradually enter markets with low cost (30%-50% lower than lithium batteries) and high safety. Suitable for mid-to-low-end electric bicycles, performing excellently in cold regions.

2. Wireless BMS Popularization: Wireless BMS using Bluetooth or Wi-Fi reduces wiring complexity, supporting remote monitoring and OTA (Over-The-Air) updates. Improves battery pack modular design for convenient maintenance.

3. High Energy Density Cells: New-generation 21700 or 4680 lithium cells provide higher energy density (200-250Wh/kg), extending range. Support fast charging technology, reducing charging time to 1-2 hours.

4. Intelligence and AI Integration: BMS integrates AI algorithms, optimizing SOC and SOH estimation, improving energy utilization rates. Predictive maintenance functions can forecast battery failures in advance.

Advances in sodium batteries and wireless BMS will reduce costs and improve user experience, particularly in range and safety aspects, injecting new vitality into the electric bicycle market.

China's Electric Bicycle Battery Export Status and Opportunities

China is the world's largest producer and exporter of electric bicycle batteries, with continued market growth in 2025 showing tremendous opportunities.

European Green Policies: EU subsidies for electric bicycles and carbon neutrality goals drive battery demand.

Southeast Asian Growth: Emerging markets like India and Vietnam show rising electric bicycle adoption rates.

Technological Advantages: Chinese manufacturers lead in sodium batteries and wireless BMS fields, meeting international market demands for cost-effective products.

Challenges: International certification requirements (UL, CE) raise export thresholds. Raw material price fluctuations may affect cost competitiveness.

Wireless BMS and intelligent fast charging are two major innovative technologies in the electric bicycle battery field, improving performance and user experience.

Features: Transmits battery data through Bluetooth, Wi-Fi, or dedicated protocols, replacing traditional wired connections.

Features: Achieves 1-2 hour rapid charging through intelligent charging algorithms and efficient chargers.

Electric bicycle batteries serve as the cornerstone of green transportation, encompassing diverse options from lead-acid to lithium to sodium-ion batteries, meeting various requirements. BMS ensures battery safety and longevity by preventing overcharging, over-discharging, and short circuits, while wireless BMS and intelligent fast charging technologies enhance convenience and efficiency. Proper installation, charging, and winter maintenance significantly extend battery cycle life, reducing maintenance costs.

In 2025, the rise of sodium batteries and intelligent technologies will drive markets toward low-cost, high-safety directions. China, as the global battery export leader, leverages technological advantages and policy support to embrace broad opportunities. From selecting high-quality brand batteries to avoiding inferior battery risks, users must focus on certifications, parameters, and usage habits.

This comprehensive guide provides practical advice to help optimize battery performance, ensuring safe, economical, and environmentally friendly riding experiences. Whether choosing between different battery technologies or implementing proper maintenance procedures, understanding these fundamentals empowers users to make informed decisions for their electric mobility needs.

www.ayaatech.com

LF LI Model Number AY-L10S200A-ES002 (4S-10S) Communication Interface RS485/CAN/BLE Charging voltage DC:12.8V-32VCC/CV(3.2V/Cell)4s-10s DC:16.8V-42VCC/CV(4.2V/Cell)4s-10s Maximal continuous charging current 200A Maximal continuous discharging current 200A Current consume in normal operation ≤15mA Current consume in sleep operation ≤150uA Balance voltage for single cell 3.5±0.05V 4.0±0.05V Over charge detection voltage 3.65±0.05V 4.25±0.05V Charge Over current detection current 220±3A Discharge Over current detection current 1 400±3A Discharge Over current detection current 2 500±3A Short Protection YES SOC 5%~8% Technical Specification Size L165 * W123 * T30 mm NTC 10K Temperature switch / ℃(the batteries temperature) Weak current switch YES Active balance YES Heater YES Braking Resistors NO Other Parameter Low temperature protection when charge 0℃ Release temperature( low temperature protection) 5℃ Over temperature protection when charge 60℃ Release temperature( over temperature protection) 55℃ Low temperature protection when discharge -15℃ Release temperature( low temperature protection) -10℃ Over temperature protection when discharge 65℃ Release temperature( over temperature protection) 55℃ Operating Temperature Range -40~+85℃ Storage Temperature Range -40~+125℃ Temperature Parameter LCD display screen YES LED light board YES Bluetooth mode YES 4G YES GPS YES Optional Configuration Smart BMS for Energy Storage SystemsA dependable, smart, and secure Battery Management System (BMS) is crucial as energy storage takes center …

www.ayaatech.com

LF LI Model Number AY-LS24S200A-H245 (18S-24S) Communication Interface RS485/CAN Charging voltage DC:51.2V CC/CV(3.2V/Cell) 16s DC:67.2V CC/CV(4.2V/Cell) 16s Maximal continuous charging current 200A Maximal continuous discharging current 200A Current consume in normal operation ≤15mA Current consume in sleep operation ≤150uA Balance voltage for single cell 3.6±0.05V 4.2±0.05V Over charge detection voltage 3.65±0.05V 4.25±0.05V Charge Over current detection current 220±3A Discharge Over current detection current 1 400±3A Discharge Over current detection current 2 500±3A Short Protection YES SOC 5%~8% Technical Specification Size L245 * W85 * T18 mm NTC 10K Temperature switch / ℃(the batteries temperature) Weak current switch YES Active balance / Heater / Braking Resistors / Other Parameter Low temperature protection when charge 0℃ Release temperature( low temperature protection) 5℃ Over temperature protection when charge 60℃ Release temperature( over temperature protection) 55℃ Low temperature protection when discharge -15℃ Release temperature( low temperature protection) -10℃ Over temperature protection when discharge 65℃ Release temperature( over temperature protection) 55℃ Operating Temperature Range -40~+85℃ Storage Temperature Range -40~+125℃ Temperature Parameter LCD display screen YES LED light board / Bluetooth mode YES 4G / GPS / Optional Configuration

www.ayaatech.com

LF LI Model Number AY-LS20S110A-H165 (16S-20S) Communication Interface RS485/CAN Charging voltage DC:51.2V~64VCC/CV(3.2V/Cell)16s~20s DC:67.2V~84VCC/CV(4.2V/Cell)16s~20s Maximal continuous charging current 110A Maximal continuous discharging current 110A Current consume in normal operation ≤20mA Current consume in sleep operation ≤100uA Balance voltage for single cell 3.6±0.05V 4.2±0.05V Over charge detection voltage 3.65±0.05V 4.25±0.05V Charge Over current detection current 130±3A Discharge Over current detection current 1 250±3A Discharge Over current detection current 2 350±3A Short Protection YES SOC 5%~8% Technical Specification Size L165 * W100 * T17 mm NTC 10K Temperature switch / ℃(the batteries temperature) Weak current switch YES Active balance / Heater / Braking Resistors / Other Parameter Low temperature protection when charge 0℃ Release temperature( low temperature protection) 5℃ Over temperature protection when charge 60℃ Release temperature( over temperature protection) 55℃ Low temperature protection when discharge -15℃ Release temperature( low temperature protection) -10℃ Over temperature protection when discharge 65℃ Release temperature( over temperature protection) 55℃ Operating Temperature Range -40~+85℃ Storage Temperature Range -40~+125℃ Temperature Parameter LCD display screen YES LED light board / Bluetooth mode / 4G / GPS / Optional Configuration 16S–20S 110A Smart BMSEngineered for Demanding Power ApplicationsOur 16S–20S 110A Smart BMS, designed for medium-to-high voltage lithium battery packs, combines intelligent …

www.ayaatech.com

LF LI Model Number AY-LS20S90A-H150 (16S-20S) Communication Interface RS485/CAN Charging voltage DC:51.2V~64VCC/CV(3.2V/Cell)16s~20s DC:67.2V~84VCC/CV(4.2V/Cell)16s~20s Maximal continuous charging current 90A Maximal continuous discharging current 90A Current consume in normal operation ≤15mA Current consume in sleep operation ≤150uA Balance voltage for single cell 3.6±0.05V 4.2±0.05V Over charge detection voltage 3.65±0.05V 4.25±0.05V Charge Over current detection current 110±3A Discharge Over current detection current 1 180±3A Discharge Over current detection current 2 280±3A Short Protection YES SOC 5%~8% Technical Specification Size L150 * W76 * T17 mm NTC 10K Temperature switch / ℃(the batteries temperature) Weak current switch YES Active balance / Heater / Braking Resistors / Other Parameter Low temperature protection when charge 0℃ Release temperature( low temperature protection) 5℃ Over temperature protection when charge 60℃ Release temperature( over temperature protection) 55℃ Low temperature protection when discharge -15℃ Release temperature( low temperature protection) -10℃ Over temperature protection when discharge 65℃ Release temperature( over temperature protection) 55℃ Operating Temperature Range -40~+85℃ Storage Temperature Range -40~+125℃ Temperature Parameter LCD display screen YES LED light board / Bluetooth mode / 4G / GPS / Optional Configuration 16S–20S 90A Smart BMS for Energy Storage Systems Precision Control | Stable Output | All-Round Protection Designed specifically for residential and …

www.ayaatech.com

LF LI Model Number AY-LS15S150A-H210 (11S-15S) Communication Interface RS485/CAN Charging voltage DC:35.2V~48VCC/CV(3.2V/Cell)11s~15s DC:46.2V~63VCC/CV(4.2V/Cell)11s~15s Maximal continuous charging current 150A Maximal continuous discharging current 150A Current consume in normal operation ≤20mA Current consume in sleep operation ≤100uA Balance voltage for single cell 3.6±0.05V 4.2±0.05V Over charge detection voltage 3.65±0.05V 4.25±0.05V Charge Over current detection current 170±3A Discharge Over current detection current 1 300±3A Discharge Over current detection current 2 400±3A Short Protection YES SOC 5%~8% Technical Specification Size L210 * W75 * T17 mm NTC 10K Temperature switch / ℃(the batteries temperature) Weak current switch YES Active balance / Heater YES Braking Resistors / Other Parameter Low temperature protection when charge 0℃ Release temperature( low temperature protection) 5℃ Over temperature protection when charge 60℃ Release temperature( over temperature protection) 55℃ Low temperature protection when discharge -15℃ Release temperature( low temperature protection) -10℃ Over temperature protection when discharge 65℃ Release temperature( over temperature protection) 55℃ Operating Temperature Range -40~+85℃ Storage Temperature Range -40~+125℃ Temperature Parameter LCD display screen / LED light board / Bluetooth mode / 4G / GPS / Optional Configuration

www.ayaatech.com

LF LI Model Number AY-LS15S110A-H180 (11S-15S) Communication Interface RS485/CAN Charging voltage DC:35.2V~48VCC/CV(3.2V/Cell)11s~15s DC:46.2V~63VCC/CV(4.2V/Cell)11s~15s Maximal continuous charging current 110A Maximal continuous discharging current 110A Current consume in normal operation ≤20mA Current consume in sleep operation ≤100uA Balance voltage for single cell 3.6±0.05V 4.2±0.05V Over charge detection voltage 3.65±0.05V 4.25±0.05V Charge Over current detection current 130±3A Discharge Over current detection current 1 250±3A Discharge Over current detection current 2 350±3A Short Protection YES SOC 5%~8% Technical Specification Size L180 * W75 * T17 mm NTC 10K Temperature switch / ℃(the batteries temperature) Weak current switch YES Active balance / Heater YES Braking Resistors / Other Parameter Low temperature protection when charge 0℃ Release temperature( low temperature protection) 5℃ Over temperature protection when charge 60℃ Release temperature( over temperature protection) 55℃ Low temperature protection when discharge -15℃ Release temperature( low temperature protection) -10℃ Over temperature protection when discharge 65℃ Release temperature( over temperature protection) 55℃ Operating Temperature Range -40~+85℃ Storage Temperature Range -40~+125℃ Temperature Parameter LCD display screen / LED light board / Bluetooth mode / 4G / GPS / Optional Configuration

www.ayaatech.com

LF LI Model Number AY-LS15S70A-H145 (11S-15S) Communication Interface RS485/RS232/CAN Charging voltage DC:35.2V~48VCC/CV(3.2V/Cell)11s~15s DC:46.2V~63VCC/CV(4.2V/Cell)11s~15s Maximal continuous charging current 70A Maximal continuous discharging current 70A Current consume in normal operation ≤20mA Current consume in sleep operation ≤150uA Balance voltage for single cell 3.6±0.05V 4.2±0.05V Over charge detection voltage 3.65±0.05V 4.25±0.05V Charge Over current detection current 80±3A Discharge Over current detection current 1 80±3A Discharge Over current detection current 2 100±3A Short Protection YES SOC 5%~8% Technical Specification Size L145 * W65 * T17 mm NTC 10K Temperature switch / ℃(the batteries temperature) Weak current switch YES Active balance / Heater / Braking Resistors / Other Parameter Low temperature protection when charge 0℃ Release temperature( low temperature protection) 5℃ Over temperature protection when charge 60℃ Release temperature( over temperature protection) 55℃ Low temperature protection when discharge -15℃ Release temperature( low temperature protection) -10℃ Over temperature protection when discharge 65℃ Release temperature( over temperature protection) 55℃ Operating Temperature Range -40~+85℃ Storage Temperature Range -40~+125℃ Temperature Parameter LCD display screen YES LED light board / Bluetooth mode / 4G / GPS / Optional Configuration

www.ayaatech.com

LF LI Model Number AY-L24S300A-ES001 (7S-24S) Communication Interface RS485/CAN/UART Charging voltage DC:22.4V~76.8VCC/CV(3.2V/Cell)7s~24s DC:29.4V~84VCC/CV(4.2V/Cell)7s~20s Maximal continuous charging current 300A Maximal continuous discharging current 300A Current consume in normal operation ≤15mA Current consume in sleep operation ≤150uA Balance voltage for single cell 3.5±0.05V 4.0±0.05V Over charge detection voltage 3.65±0.05V 4.25±0.05V Charge Over current detection current 320±3A Discharge Over current detection current 1 600±3A Discharge Over current detection current 2 800±3A Short Protection YES SOC 5%~8% Technical Specification Size L206 * W162 * T40 mm NTC 10K Temperature switch / ℃(the batteries temperature) Weak current switch YES Active balance YES Heater YES Braking Resistors YES Other Parameter Low temperature protection when charge 0℃ Release temperature( low temperature protection) 5℃ Over temperature protection when charge 60℃ Release temperature( over temperature protection) 55℃ Low temperature protection when discharge 15℃ Release temperature( low temperature protection) 10℃ Over temperature protection when discharge 65℃ Release temperature( over temperature protection) 55℃ Operating Temperature Range 40~+85℃ Storage Temperature Range 40~+125℃ Temperature Parameter LCD display screen YES LED light board TES Bluetooth mode YES 4G YES GPS YES Optional Configuration

www.ayaatech.com

LF LI Model Number AY-CX24S200A-H093 (18S-24S) Communication Interface RS485/CAN Charging voltage DC:57.6V~76.8V CC/CV(3.2V/Cell)18s-24s DC:75.6V~84 CC/CV(4.2V/Cell)18s-20s Maximal continuous charging current 200A Maximal continuous discharging current 200A Current consume in normal operation ≤15mA Current consume in sleep operation ≤150uA Balance voltage for single cell 3.6±0.05V 4.2±0.05V Over charge detection voltage 3.65±0.05V 4.25±0.05V Charge Over current detection current 220±3A Discharge Over current detection current 1 400±3A Discharge Over current detection current 2 500±3A Short Protection YES SOC 5%~8% Technical Specification size L235 * W100 * T16 mm NTC 10K Temperature switch / ℃(the batteries temperature) Weak current switch YES Active balance / Heater / Braking Resistors / Other Parameter Low temperature protection when charge 0℃ Release temperature( low temperature protection) 5℃ Over temperature protection when charge 60℃ Release temperature( over temperature protection) 55℃ Low temperature protection when discharge -15℃ Release temperature( low temperature protection) -10℃ Over temperature protection when discharge 65℃ Release temperature( over temperature protection) 55℃ Operating Temperature Range -40~+85℃ Storage Temperature Range -40~+125℃ Temperature Parameter LCD display screen / LED light board / Bluetooth mode YES 4G / GPS / Optional Configuration 18S–24S 200A Smart BMS for Golf CartsFor high-performance golf carts that require both power and dependability, our 18S–24S 200A …

www.ayaatech.com

Model Number AY-CX20S200A-H105(20S) Communication Interface RS485 Charging voltage DC:64V CC/CV(3.2V/Cell) 20s DC:84V CC/CV(4.2V/Cell) 20s Maximal continuous charging current 200A Maximal continuous discharging current 200A Current consume in normal operation ≤15mA Current consume in sleep operation ≤150uA Balance voltage for single cell 3.6±0.05V 4.2±0.05V Over charge detection voltage 3.65±0.05V 4.25±0.05V Charge Over current detection current 120±3A Discharge Over current detection current 1 200±3A Discharge Over current detection current 2 300±3A Short Protection YES SOC 5%~8% Technical Specification size L181 * W86 * T16 mm NTC 10K Temperature switch / ℃(the batteries temperature) Weak currentswitch YES Active balance / Heater / Braking Resistors / Other Parameter Low temperature protection when charge 0℃ Release temperature( low temperature protection) 5℃ Over temperature protection when charge 60℃ Release temperature( over temperature protection) 55℃ Low temperature protection when discharge – 15℃ Release temperature( low temperature protection) -10℃ Over temperature protection when discharge 65℃ Release temperature( over temperature protection) 55℃ Operating Temperature Range -40~+85℃ Storage Temperature Range -40~+125℃ Temperature Parameter LCD display screen YES LED light board / Bluetooth mode YES 4G / GPS / Optional Configuration

www.ayaatech.com

LF LI Model Number AY-CX20S100A-H092 (20S) Communication Interface RS485 Charging voltage DC:64V CC/CV(3.2V/Cell) 20s DC:84V CC/CV(4.2V/Cell) 20s Maximal continuous charging current 100A Maximal continuous discharging current 100A Current consume in normal operation ≤15mA Current consume in sleep operation ≤150uA Balance voltage for single cell 3.6±0.05V 4.2±0.05V Over charge detection voltage 3.65±0.05V 4.25±0.05V Charge Over current detection current 120±3A Discharge Over current detection current 1 200±3A Discharge Over current detection current 2 300±3A Short Protection YES SOC 5%~8% Technical Specification Size L181 * W86 * T16 mm NTC 10K Temperature switch / ℃(the batteries temperature) Weak current switch YES Active balance / Heater / Braking Resistors / Other Parameter Low temperature protection when charge 0℃ Release temperature( low temperature protection) 5℃ Over temperature protection when charge 60℃ Release temperature( over temperature protection) 55℃ Low temperature protection when discharge -15℃ Release temperature( low temperature protection) -10℃ Over temperature protection when discharge 65℃ Release temperature( over temperature protection) 55℃ Operating Temperature Range -40~-85℃ Storage Temperature Range -40~+125℃ Temperature Parameter LCD display screen / LED light board / Bluetooth mode YES 4G / GPS / Optional Configuration

www.ayaatech.com

LF LI Model Number AY-CX8S200A-H104 (8S) Communication Interface RS485 Charging voltage DC:25.6V CC/CV(3.2V/Cell) 8s DC:33.6V CC/CV(4.2V/Cell) 8s Maximal continuous charging current 200A Maximal continuous discharging current 200A Current consume in normal operation ≤15mA Current consume in sleep operation ≤150uA Balance voltage for single cell 3.6±0.05V 4.2±0.05V Over charge detection voltage 3.65±0.05V 4.25±0.05V Charge Over current detection current 220±3A Discharge Over current detection current 1 400±3A Discharge Over current detection current 2 500±3A Short Protection YES SOC 5%~8% Technical Specification Size L165 * W80 * T16 mm NTC 10K Temperature switch / ℃(the batteries temperature) Weak current switch YES Active balance / Heater YES Heater / Other Parameter Low temperature protection when charge 0℃ Release temperature( low temperature protection) 0℃ Over temperature protection when charge 60℃ Release temperature( over temperature protection) 55℃ Low temperature protection when discharge -15℃ Release temperature( low temperature protection) -10℃ Over temperature protection when discharge 65℃ Release temperature( over temperature protection) 55℃ Operating Temperature Range -40~+85℃ Storage Temperature Range -40~+125℃ Temperature Parameter LCD display screen YES LED light board / Bluetooth mode YES 4G / GPS / Optional Configuration

| Battery Series | Model | Picture | Working Current | Balance | Size | Remark |

|---|---|---|---|---|---|---|