AYAA, a leading China manufacturer, specializes in high-quality 12V lithium battery management systems and 8s BMS solutions. We provide customized BMS technology, wholesale options, and reliable product supply for diverse applications.

AYAA, a leading China manufacturer, specializes in high-quality 12V lithium battery management systems and 8s BMS solutions. We provide customized BMS technology, wholesale options, and reliable product supply for diverse applications.

In the rapidly evolving landscape of renewable energy and storage solutions, the 12V battery management system (BMS) remains a cornerstone for applications like RVs, off-grid solar systems, portable power stations, and marine environments. Among these, the 8S 12V BMS stands out for its robust management of 8-series lithium-ion or lithium iron phosphate (LiFePO4) battery packs, ensuring safety, efficiency, and longevity. This article provides an in-depth exploration of the 12V lithium battery management system, focusing on its design principles, core functionalities, and practical applications, with a particular emphasis on the 8S 12V BMS.

A 12V battery management system is an electronic control unit designed to monitor, protect, and manage a 12-volt battery or battery pack. Its primary role is to oversee critical parameters such as voltage, current, and temperature, ensuring the battery operates within safe limits. This prevents risks like overcharging, over-discharging, and short circuits, which are particularly critical for lithium-based batteries due to their sensitivity to voltage fluctuations and smaller safety margins compared to lead-acid batteries.

The 12V lithium battery management system enhances battery performance by extending lifespan, improving energy efficiency, and ensuring operational stability. For applications like RVs, solar storage, and portable power, a 12V BMS is indispensable for maintaining system reliability.

The differences between lithium and lead-acid battery management systems stem from their distinct electrochemical properties and safety requirements. A 12V lithium battery management system is designed for precision and intelligence, while lead-acid BMS systems are simpler and less sophisticated. Below is a comparison:

|

Feature |

12V Lithium BMS |

Lead-Acid BMS |

| Charge/Discharge Control | Precisely monitors individual cell voltage and current | Monitors overall battery pack voltage |

| Balancing Function | Supports active/passive cell balancing | Typically lacks balancing mechanisms |

| Safety Mechanisms | Includes overcharge, over-discharge, overcurrent, short-circuit, and temperature protection | Limited protection features |

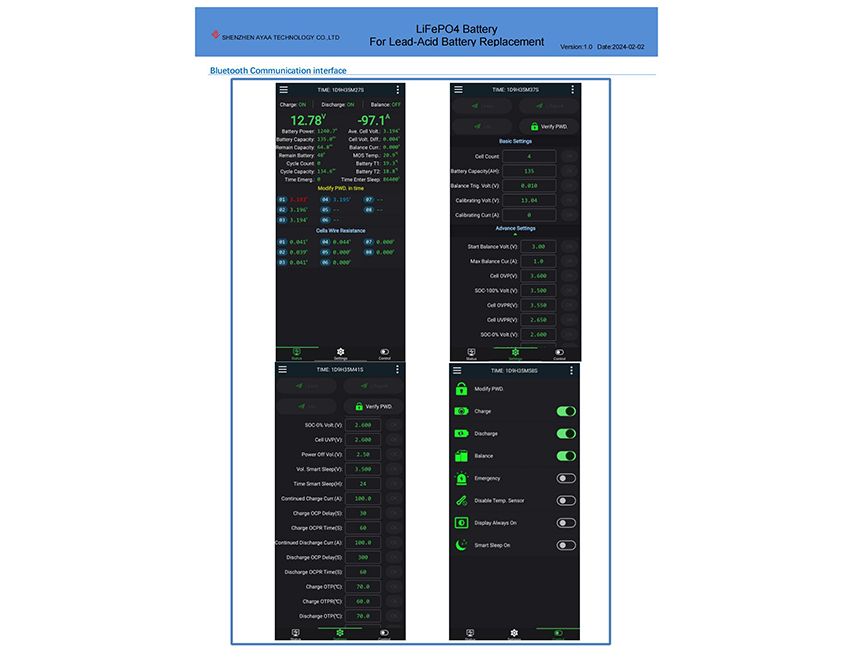

| Intelligence Level | Supports communication modules (e.g., CAN, UART) for remote monitoring | Basic protection circuitry |

The 12V lithium battery management system prioritizes high-precision management, making it ideal for applications requiring reliability and efficiency, while lead-acid systems rely on simpler circuits due to their more forgiving electrochemical nature.

The term “8S” in an 8S 12V BMS refers to a battery management system designed for an 8-series (8S) lithium battery configuration, where eight cells are connected in series. The nominal voltage of each cell depends on the battery chemistry:

Despite the higher nominal voltage, the 8S 12V BMS is labeled as a “12V” system because it is tailored for applications requiring a stable 12V output, often achieved through a DC-DC converter to step down the voltage for RV, solar, or portable power systems. Thus, the 8S 12V BMS bridges the gap between the high-voltage battery pack and the 12V load requirements.

A robust 12V battery management system comprises several core modules, each serving a specific function to ensure safe and efficient battery operation. Below is an overview of the key components:

Monitors individual cell voltages to ensure they remain within safe thresholds.

Uses shunt resistors or Hall-effect sensors to measure current flow, enabling overcurrent protection.

Prevents thermal runaway or low-temperature charging issues using NTC thermistors or similar sensors.

Employs active or passive balancing to equalize cell voltages, enhancing charge consistency.

Manages charge and discharge paths, providing protection by interrupting circuits during faults.

Facilitates data exchange with external devices for real-time monitoring or system integration.

1. Each cell connects to the main control chip via voltage dividers or operational amplifiers.

2. The chip processes data and executes logic-based decisions.

3. MOSFET drivers control the charge/discharge paths.

4. Temperature sensors adjust protection thresholds dynamically.

5. Data is transmitted to external displays or remote servers via communication interfaces.

In an 8-series lithium battery pack, manufacturing variances can lead to voltage inconsistencies among cells, reducing capacity and lifespan over time. The 8S 12V BMS addresses this through cell balancing, implemented in two ways:

1. The 8S 12V BMS monitors each cell’s voltage.

2. If a cell exceeds the balancing threshold (e.g., 4.2V for Li-ion), the balancing circuit activates.

3. Passive balancing discharges the high-voltage cell through a resistor, while active balancing redistributes energy to lower-voltage cells.

4. Balancing stops when all cells are within an acceptable voltage range.

Tip: When selecting a 12V BMS, verify whether it supports active balancing and allows customizable voltage thresholds to match your battery chemistry.

The 12V battery management system operates through a closed-loop process, managing the battery from charging to discharging to ensure safety and efficiency.

This workflow ensures the 12V lithium battery management system maximizes safety and efficiency across all operating stages.

A high-quality 12V lithium battery management system must deliver the following six essential functions to ensure safety, performance, and longevity:

Disconnects the charging circuit when cell voltages exceed safe limits (e.g., 4.2V for Li-ion).

Halts discharge when cell voltages drop below the minimum threshold (e.g., 2.5V for Li-ion).

Interrupts the circuit during excessive current flow, such as in overload or fault conditions.

Responds in microseconds to disconnect the circuit during a short circuit, preventing damage or fires.

Uses sensors (e.g., NTC) to monitor cell and MOSFET temperatures, pausing operations in extreme conditions.

Equalizes cell voltages to maintain consistency, improving efficiency and extending battery life.

These functions collectively make the 12V BMS the “safety brain” of lithium battery systems.

Omitting a 12V battery management system in a lithium battery setup is a dangerous oversight, especially for applications prioritizing safety and longevity. Without a 12V lithium battery management system, risks include:

A 12V BMS is critical for applications like energy storage systems, RV power, marine systems, power tools, and outdoor lighting, ensuring safety and reliability.

Beyond protection, an 8S 12V BMS actively extends battery lifespan through:

Tip: Active balancing BMS units can extend battery life by 15-25% compared to passive systems, especially in high-capacity setups.

Proper wiring is critical for the 8S 12V BMS to function correctly. Below is a detailed guide:

Solder the B- terminal to the battery pack’s negative end.

Attach P- to the load or charger’s negative terminal.

Some 12V BMS units have a dedicated charging negative port.

The 12V battery management system, particularly the 8S 12V BMS, is the backbone of safe and efficient lithium battery operation in applications like RVs, solar storage, and marine systems. By integrating precise monitoring, robust protection, and intelligent balancing, the 12V lithium battery management system ensures safety, extends battery life, and optimizes performance. Whether you’re building a DIY energy storage solution or upgrading an RV power system, selecting and correctly installing a high-quality 12V BMS is non-negotiable for reliability and safety.

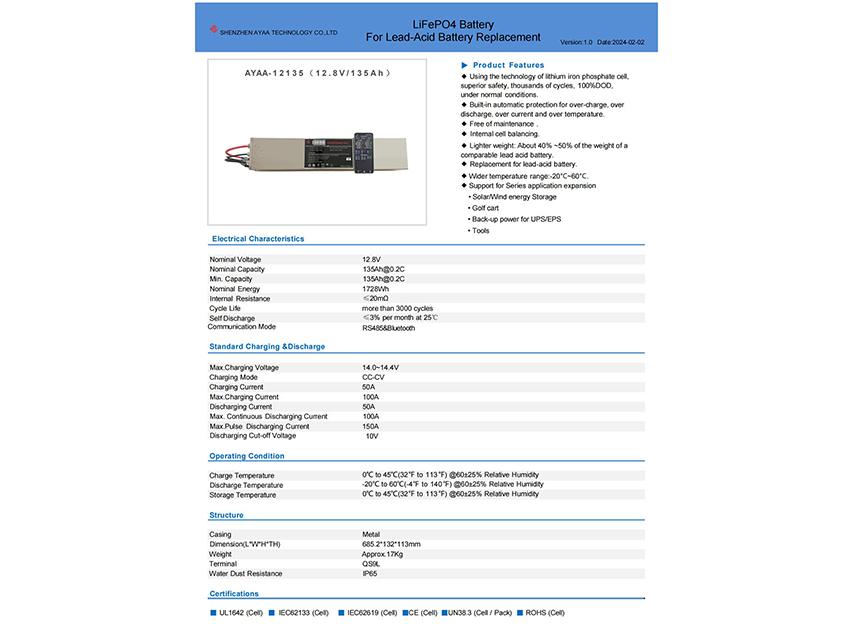

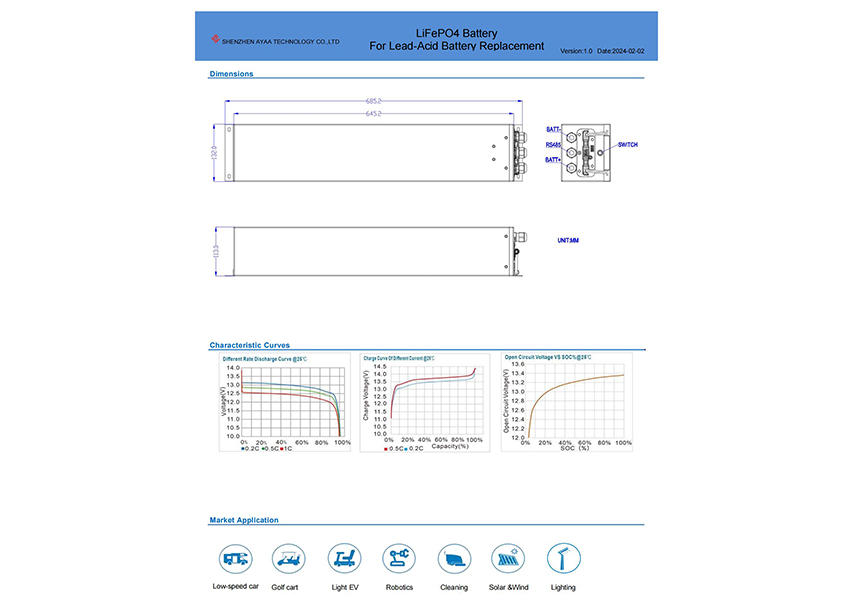

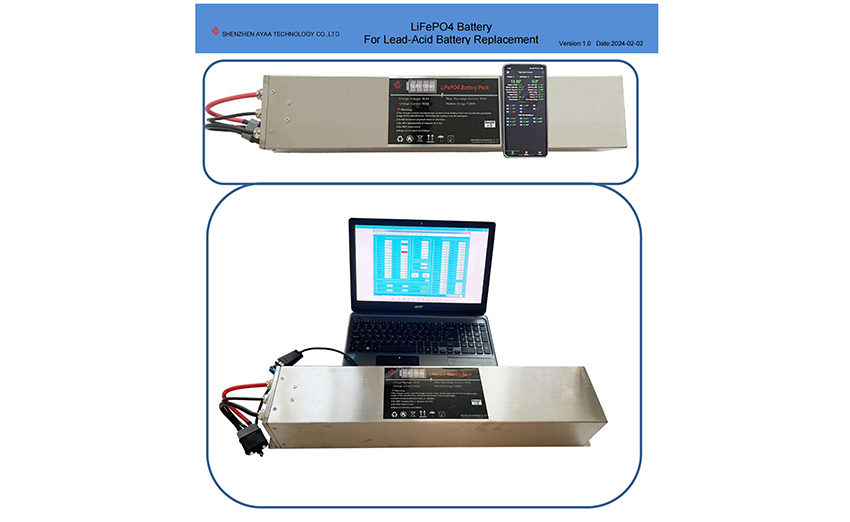

12V LiFePO4 Battery Pack