Home About Us EVENTS & NEWS Why an Advanced EV BMS Is the Heart of Modern Electric Vehicles

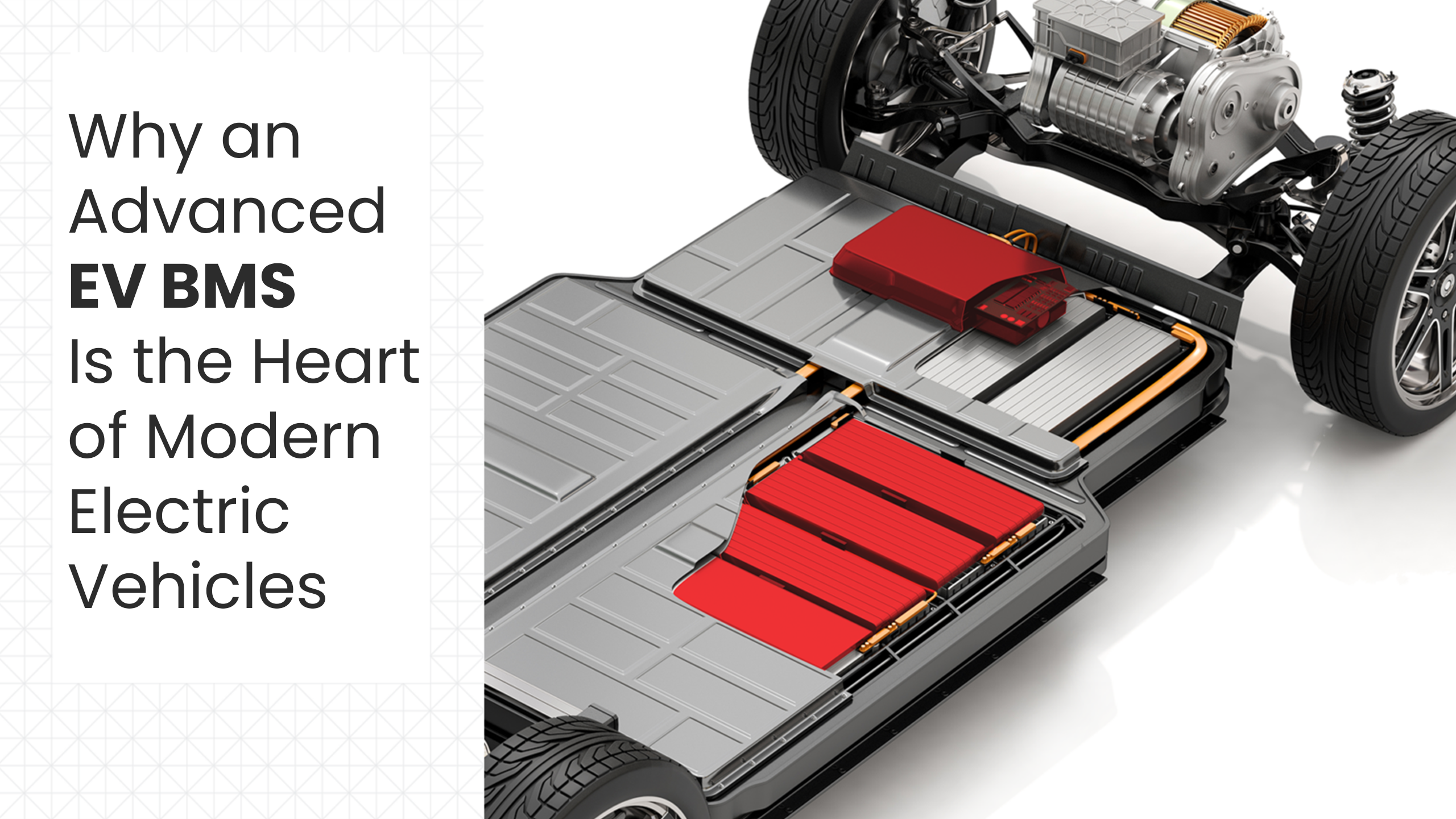

Why an Advanced EV BMS Is the Heart of Modern Electric Vehicles

Why an Advanced EV BMS Is the Heart of Modern Electric Vehicles

Introduction: The Crucial Role of BMS in Lithium-Ion Battery Systems

The Battery Management System (BMS) is the unseen leader of every electric vehicle (EV) in the exciting age of sustainable mobility.

It guarantees the safe, effective, and intelligent operation of lithium-ion batteries, which are valued for their great energy density.

The entire vehicle runs the risk of overheating, cell damage, or even catastrophic failure in the absence of an appropriate EV BMS.

The market for smarter, more capable BMS systems has grown as the demand for electric vehicles rises.

The ecosystem is changing quickly, from cloud-connected diagnostics to smart lithium ion BMS.

Whether you’re a fleet engineer or a do-it-yourselfer, this article will help you understand, select, and maximize the best lithium ion BMS for your electric car project.

What Is a Lithium Ion BMS and How Does It Work?

A specialized electronic circuit known as a lithium-ion battery management system keeps track of and regulates the charging and discharging of lithium-ion battery cells. Among its primary duties are:

- Monitoring individual cell voltages and total pack voltage

- Measuring temperature across cells

- Controlling charging and discharging via relays or MOSFETs

- Cell balancing to prevent overcharging

- Protection from overvoltage, undervoltage, overcurrent, short circuit, and overheating

Because lithium-ion chemistry is so sensitive, a lithium ion BMS circuit is essential.

To maintain everything within safety limits, systems such as a 10s lithium ion BMS (for 10 series batteries) incorporate heat sensors, current sensors, and balance leads.

Types and Classifications of Lithium Ion BMS

BMS systems are categorized by structure, function, and application:

- Centralized BMS: All monitoring is in one location—common in smaller packs.

- Distributed BMS: Modules are placed close to each battery string—ideal for large EVs.

- String Size: From 1S (1 cell) to 24S+; e.g., 10s is widely used in e-bikes and DIY packs.

- Current Handling: Low power (under 50A) to high power (200A+ for EVs).

- Basic vs Smart: A smart lithium ion BMS includes features like Bluetooth or CAN communication.

- Application-Based: EVs, solar storage, drones, or portable power stations all require specific BMS configurations.

Key Parameters to Choose the Right EV BMS

Choosing the right battery management system for EV applications means getting the details right:

- Battery Configuration: Match your BMS to your battery pack’s series/parallel layout.

- Rated and Peak Current: BMS should exceed your motor’s draw under acceleration.

- Balancing Method: Passive balancing is simpler; active balancing improves performance.

- Communication Needs: Look for Bluetooth lithium ion BMS, or CAN/RS485 support for system integration.

- Physical Size: Consider enclosure space and heat dissipation.

- Certifications: UL, CE, and RoHS ensure safety and compliance.

Best Lithium Ion BMS Products of 2025

2025’s top BMS systems balance power, intelligence, and flexibility:

- Ayaa Tech Series: High-end, robust EV BMS with multi-protocol support, smart balancing, and a mobile app. Ideal for EVs and solar storage.

- JBD Smart BMS: Open-source friendly, great for DIY lithium ion BMS projects.

- Daly BMS: Reliable for mid-range needs, supports up to 200A.

- REC BMS: Advanced diagnostics and modular design—excellent for commercial EVs.

- Heltec BMS: Upcoming brand offering flexible options for custom packs.

Installation and Wiring Guide

Installing a lithium ion battery management system properly ensures safety and functionality:

- Preparation: Disconnect all power and check voltage levels.

- Balance Lead Connection: Connect leads in order, using a reliable lithium ion BMS wiring diagram.

- Power Path Design: Use appropriate gauge cables and install fuses.

- Sensor Placement: Put temperature sensors near heat sources and center of the pack.

- Final Check: Test all connections before powering up.

Common mistakes include inverted balance wires, undersized cables, and skipping pre-charge circuits.

Configuration and Parameter Settings

To optimize performance, configure your EV BMS as follows:

- Set chemistry type (Li-ion, LiFePO4, etc.)

- Define voltage thresholds (overcharge, undervoltage)

- Choose balancing strategy

- Configure communication (e.g., CAN baud rate, Bluetooth access)

- Adjust temperature cutoffs for safety

Most smart lithium ion BMS systems offer PC or app interfaces for customization.

Troubleshooting Common BMS Issues

Understanding BMS behavior helps with diagnostics:

- Protection Triggered? Check fault logs—common causes include overcurrent or thermal spike.

- Balancing Not Working? Verify wiring and inspect passive resistors.

- No Communication? For Bluetooth issues, check app permissions and re-pair the device.

- Pack Not Charging? Look for cut-off triggers or incompatible charger profiles.

For advanced users, firmware updates and oscilloscope testing can help isolate faults in your lithium ion BMS circuit.

Advanced Applications of EV BMS

The future of BMS is smart and connected:

- Battery Health Analytics: Utilize BMS logs to monitor capacity fade and cycle count.

- Integration with EMS: For load optimization, integrate Energy Management Systems data with BMS data.

- Cloud Monitoring: updates in real time for distant systems or fleets.

- Custom Firmware: Adjust criteria and algorithms according to usage trends.

- LiFePO4 vs Lithium Ion BMS: Recognize how protection factors are influenced by chemistry.

DIY Lithium Ion BMS Project Guide

It is feasible for entrepreneurs or hobbyists to construct their own system:

- Gather components: BMS board, wiring, sensors, protection circuits.

- Use platforms like Arduino or Raspberry Pi for control logic.

- Explore open-source firmware and community forums.

- Test with bench power supplies and dummy loads.

- Expand features—such as remote monitoring or GPS logging.

A do-it-yourself lithium ion BMS is more than simply a project; it’s an educational opportunity.

FAQ

Q1: What is BMS in EV?

A:In order to maintain the battery cells within a safe operating range, the BMS, which is usually an embedded system and a specially created electronic regulator, monitors and regulates a number of battery characteristics, including temperature, voltage, and current.

Q2:What is the function of the BMS?

A:The brain of the battery system is an electrical device called the battery management system (BMS). Safety and protection, cell balancing, status monitoring, thermal management system, data collecting, and energy management system are some of the primary roles of BMS, as illustrated in Fig.

Q3: What is BMS in Tesla?

A:With individual cell temperatures varying from -20°C to 60°C under normal operating conditions, Tesla’s battery management systems manage intricate thermal and electrical interactions across thousands of cells.

Q4: What is BMS system in cars?

A:One crucial system that keeps an eye on and regulates the battery’s condition is the BMS. By using this feature, the BMS maximizes battery performance while maintaining battery safety. It is anticipated that an increasing number of BMSs will be integrated into EVs as EV production increases.

Q5: Is BMS an ECU?

For instance, since a battery management system (BMS) is a distinct computer system that carries out a particular function, it would be regarded as an ECU.

An EV BMS is more than just a part; it’s the brains behind your electric car, enhancing everything from performance to safety.

Selecting the finest lithium ion BMS is essential for enabling longer life, more safety, and more intelligent control as lithium-ion battery systems become more complicated.

Make no mistake: the future is electric, and the BMS is the vital component that keeps it going, whether you’re building a prototype EV, updating your fleet, or creating a do-it-yourself lithium ion BMS for your own project.

News Recommend

-

How does AYAATECH BMS work in E-scooters

01/16/2025