Home About Us EVENTS & NEWS Understanding BMS for Car Battery: Key Technologies and How They Empower EVs

Understanding BMS for Car Battery: Key Technologies and How They Empower EVs

Understanding BMS for Car Battery: Key Technologies and How They Empower EVs

In the electric vehicle (EV) revolution, the bms for car battery is the brain behind every high-performance battery.

As automotive technology evolves, more and more manufacturers are looking to advanced automotive battery BMS solutions to improve energy efficiency, safety, and real-time diagnostics.

We will learn about the concepts, core working principles, and application considerations of automotive battery BMS.

Concept of BMS for Car Battery

A BMS for car battery is an integrated electronic system designed to monitor, control, and protect the performance of a vehicle’s rechargeable battery pack.

It acts as the control center that ensures battery cells operate within their optimal parameters.

Voltage Monitoring: Tracks individual cell voltages to prevent overcharge or over-discharge.

Temperature Control: Prevents thermal runaway and manages heat dissipation.

Current Regulation: Detects overcurrent scenarios and responds appropriately.

State Estimation: Calculates the battery’s State of Charge (SOC) and State of Health (SOH).

Balancing: Maintains voltage balance among cells for optimal battery performance.

A modern BMS for car battery is indispensable in ensuring not just battery longevity, but also safe and reliable vehicle operation.

How Does a Car Battery BMS Work?

The core working principle of a BMS for car battery revolves around three technological layers:

1.Data Collection – Using sensors and circuits, the BMS collects real-time data on voltage, current, and temperature.

2.Data Processing & Decision Making – A microcontroller interprets the data, compares it with pre-set safety thresholds, and determines the correct response.

3.Control Actions – Based on decisions, the BMS may activate cooling systems, disconnect loads, or send warnings to the vehicle’s central ECU.

Advanced BMS also support CANbus, RS485, and UART communications to ensure seamless integration with the car’s electronics and telematics systems.

Key Advantages of BMS for Car Batteries

Enhanced Safety

A BMS (Battery Management System) protects the car battery from overcharging, over-discharging, overheating, and short circuits, significantly reducing the risk of thermal runaway or battery failure.

Longer Battery Life

By maintaining optimal operating conditions and balancing individual cells, the BMS extends the overall lifespan of the car battery.

Real-Time Monitoring

The BMS continuously monitors voltage, current, and temperature, ensuring accurate data for diagnostics and predictive maintenance.

Improved Energy Efficiency

Intelligent charge and discharge control helps maximize usable battery capacity, increasing the driving range of electric vehicles.

State Estimation Functions

Advanced algorithms calculate the State of Charge (SOC), State of Health (SOH), and other parameters, supporting better energy management and performance planning.

Smart Communication

Equipped with communication protocols like CANBus, the BMS integrates seamlessly with the vehicle’s control system, enabling real-time data exchange and diagnostics.

Cell Balancing

Passive or active balancing ensures all battery cells operate within optimal ranges, preventing cell degradation and increasing system reliability.

Application of BMS for Car Battery

A high-quality BMS for car battery is critical for:

Passenger Electric Vehicles (EVs): From compact cars to SUVs.

Commercial Electric Vehicles: Like delivery vans and light-duty trucks.

Micro-EVs and Two-Wheelers: E-scooters and electric motorcycles.

Hybrid Vehicles: Where battery and ICE integration demands tight monitoring.

These applications demand robust, efficient, and adaptable battery management solutions capable of responding to dynamic vehicle conditions.

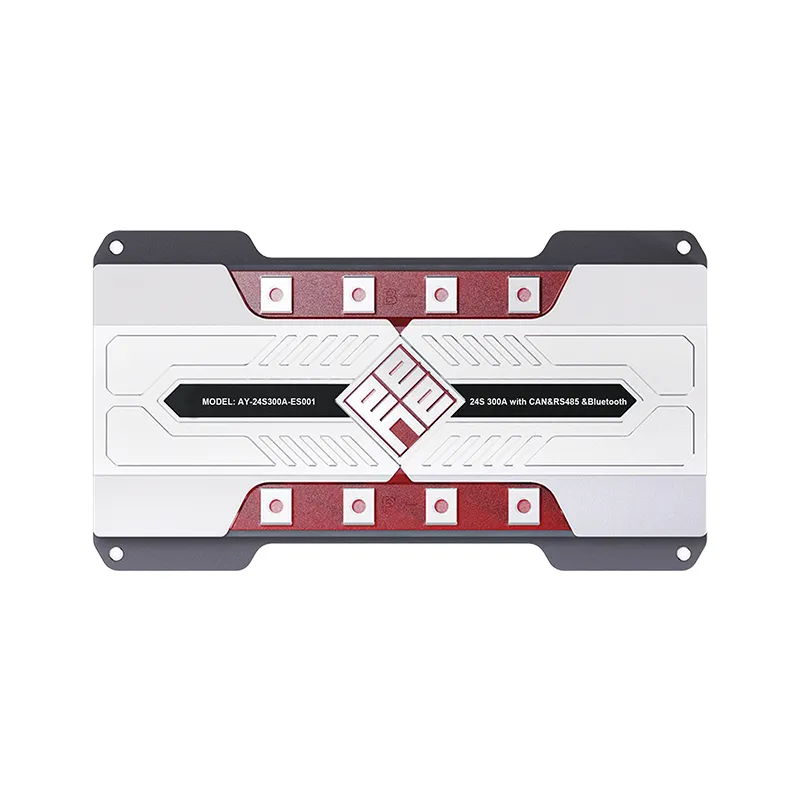

AY-L24S300A-ES001 (7S-24S)

The AY-L24S300A-ES001 is a flagship product specifically engineered for broad voltage configurations and demanding automotive applications.Key Advantages:

Voltage Support: 7S to 24S lithium battery packs

Smart Monitoring: CANbus-based real-time telemetry

High Current Handling: Up to 300A, ideal for EV traction systems

Safety Protocols: Over-voltage, under-voltage, temperature, short circuit, and overcurrent protection

Applications: Mid- to large-size EVs, mobile power systems, and high-performance electric vehicles

For automakers or system integrators seeking a reliable BMS for car battery, this model offers a balance of scalability, protection, and communication.

AY-L10S200A-ES002 (3S-10S)

Compact yet powerful, the AY-L10S200A-ES002 is designed for more modular and lightweight EV systems.

Specifications & Benefits:

Voltage Range: 3S to 10S battery configurations

Communication: Supports both CAN and UART

Material Quality: Industrial-grade PCB, long lifecycle components

Compact Design: Easy to integrate into smaller vehicle compartments

Applications: E-bikes, e-scooters, compact city EVs, medical carts

Its size, compatibility, and reliability make it a favorite BMS for car battery in small-format electric platforms.

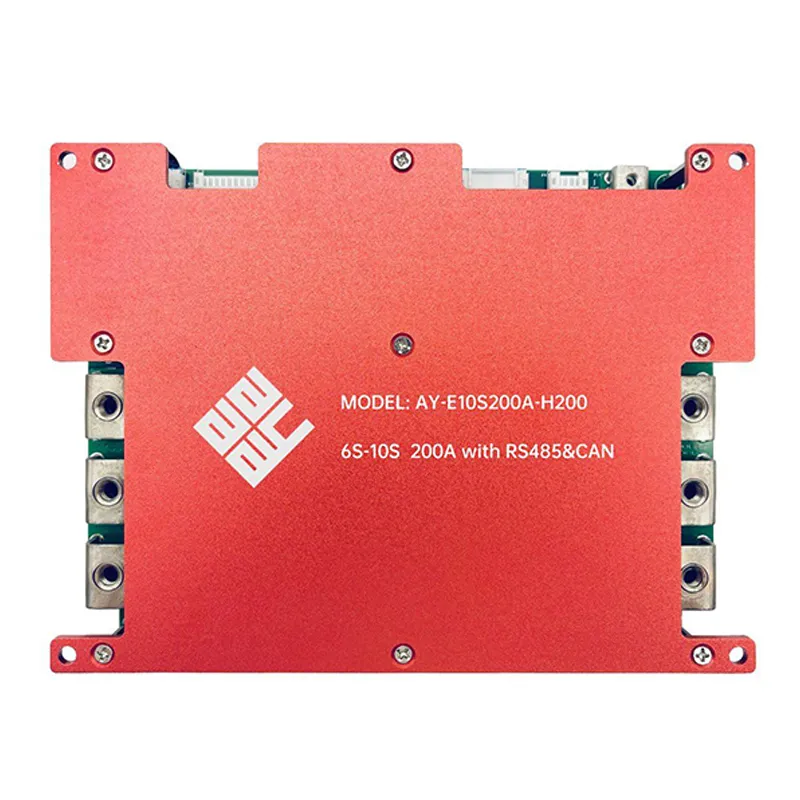

AY-LS10S200A-H200 (6S-10S)

Designed for more versatile integration and smart parallel applications, the AY-LS10S200A-H200 meets high-performance expectations.Core Features:

Voltage Support: 6S–10S

Parallel Compatibility: Supports multi-pack parallel connection

Communication Protocols: CANbus, RS485

Durability: Optimized for thermal efficiency and harsh environments

Use Cases: Fleet vehicles, light trucks, off-grid EVs

For developers building modular powertrains, this model delivers what modern BMS for car battery solutions must provide: flexibility, robustness, and intelligence.

Product Comparison Table

AY-L24S300A-ES001 7S–24S 300A CANbus Application: Mid/large EVs, mobile power

AY-L10S200A-ES002 3S–10S 200A CAN, UART Application: E-bikes, scooters, compact EVs

AY-LS10S200A-H200 6S–10S 200A CAN, RS485 Application: Fleets, off-grid EVs

This comparative overview showcases how each product aligns with the functional expectations for different BMS for car battery applications.

FAQ

Q1: Why is a BMS for car battery important in EVs?

A: It ensures safety, extends battery life, prevents damage, and provides real-time data for better driving performance.

Q2: Can one BMS work with different battery chemistries?

A: Yes, AyaaTech BMS products support multiple chemistries like Li-ion, LiFePO4, and NMC.

Q3: What makes AyaaTech’s BMS solutions reliable?

A: Over 18 years of R&D experience, ISO-certified manufacturing, and a global customer base across EV, robotics, and energy sectors.

Q4: Can these BMS products be customized?

A: Absolutely. Shenzhen Ayaa Technology offers tailored firmware, communication protocols, and structural adaptations.

Advantages of choosing Shenzhen Ayaa Technology Co.

With more than 18 years of experience in BMS development and deployment, Shenzhen Ayaa Technology Co., Ltd. stands at the forefront of intelligent energy solutions.

For companies sourcing a reliable BMS for car battery, AyaaTech provides:

400+ BMS model options ranging from 1S to 35S

Support for current loads up to 320A

Communication via CAN, SMBus, RS485, Bluetooth

Customization services for protocol, structure, and firmware

Proven use in EVs, drones, robotics, forklifts, and more

When you choose AyaaTech, you choose innovation, safety, and global engineering expertise.

Understanding the significance of a BMS for car battery is key to mastering modern EV performance.

Whether it’s a lightweight scooter or a powerful electric SUV, having the right battery management system is crucial.

With models like AY-L24S300A-ES001, AY-L10S200A-ES002, and AY-LS10S200A-H200, Shenzhen Ayaa Technology delivers world-class solutions tailored for a wide range of applications.

If you’re seeking smart, scalable, and reliable BMS for car battery systems—AyaaTech is the partner you can trust.